Brown University's Thermal Efficiency Project-2

Brown University

Project Overview

Brown University is a 6.5 million sq. ft. research university campus founded in 1764 in Providence, Rhode Island. Its annual energy bill is $20 million. It serves 7,000 undergraduate students, 2,600 graduate students, 585 medical school students, and 6,000 summer, visiting or online students. The campus undertook the Thermal Efficiency Project to reduce energy losses and overall fossil fuel consumption, help to achieve the campus’s ambitious 42% greenhouse gas emissions reduction goal by 2020, and ultimately enable future decarbonization of the central heating plant. The centerpiece of the project was an extensive reengineering and upgrading of their district energy network dating from 1967. This was all part of the campus’s Sustainability Strategic Plan. This project has provided momentum with its platform, which has allowed Brown to update its already ambitious goals: The university is now committed to cutting its greenhouse gas emissions to net-zero by 2040, with a 75% reduction by 2025. Engaging in a transformational project without disrupting the campus’ regular activities is extremely challenging, requiring exemplary engineering and construction planning. In collaboration with many stakeholders – including the President, Executive VP of Finance and Administration, Board of Trustees and an academic group – Brown favored a transformational project with a global approach. Facilities Management and the Office of Sustainability partnered with an integrated design-build firm to design, plan and implement this ambitious project.

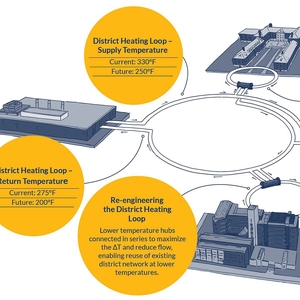

Before the project, a central steam plant supplied heat to a high-temperature, high-pressure hot water district heating network. From the district heating network, 33 energy hubs provided heating to separate local heating loops supplying 93 of the 228 campus buildings. Of these hubs, 22 provided hot water for local heating loops. The remaining 11 energy hubs provided steam to other buildings. In some cases, that steam was used for intermediate small district heating and then converted again to produce hot water for building heating. This sequence of heat transfer between the central plant and the end-uses (sometimes from steam to high-pressure hot water and back to steam and to hot water again) was detrimental to the overall efficiency. Of the 11 steam-producing hubs, six were already budgeted for upgrades. Brown was able to merge asset renewal projects and energy efficiency improvements within one large project. Combining these two strategies made sense, as any infrastructure upgrade benefits from energy efficiency. The university chose to partner with an integrated engineering and construction firm. An integrated approach – in which a single accountable firm (Ecosystem) handled all aspects of the project design, implementation, and optimization – supported the complexity of this project, both on the design and implementation sides. Working closely with Brown’s Facilities Management department, Ecosystem’s team of experts was able to address potential construction challenges during project design and later benefit from on-site engineering capabilities throughout the construction. They invested time auditing the buildings and their heating/process loads, developing custom solutions for each building as well as the district network reengineering and the central plant conversion. The main technical challenges of the Thermal Efficiency Project involved: 1. Converting the steam loads in each hub 2. Lowering the supply temperature and still be able to meet buildings’ needs 3. Maintaining the temperature differential with a lower supply temperature

Stage 1: Building-level strategy to reduce the steam needs from the network The project first involved reducing the need for steam from the district network, either by converting steam loads to hot water, or generating steam on-site for buildings that required steam for specific processes. During the design phase, it was essential to follow a case-by-case approach, as some buildings required institution-specific plans or represented greater value overall for conversion.

Across the campus, each individual steam load, whether a building or process, was analyzed. Through improvements in buildings across the campus, steam and high-temperature loads were removed from the district heating network. For example, many dorms were historic buildings that were heated by old, small-scale steam district networks. These hubs were converted during the summer session when students were not on campus. In buildings such as the library, where the cost of a steam to hot water heating system conversion was prohibitive, new steam boilers were installed on the roof, removing that steam load from the district heating network. In more complex buildings, such as the biomedical research complex, where steam and hot water needs co-exist, the local steam load was provided by new steam boilers, but overall building efficiency was maintained by performing heat recovery on the flue gas in the chimney. The captured heat is now used to preheat and reheat some ventilation systems. An innovative aspect of the project was a new run-around recovery loop installed in a 100% fresh air system by replacing the steam coil and installing a new custom-designed dual-use coil for heat recovery and heating. This innovative solution required only one shutdown, important for a building housing sensitive scientific research.

Stage 2: Lowering the district network temperature Although the high-temperature and process loads were removed from the district network, space heating still accounted for a big portion of the energy needs. The amount of energy transmitted in a network is related to both the temperature and the amount of water flow. Providing a similar amount of energy with a lower-temperature network would typically mean increasing the flow or replacing a major part of the network with bigger pipes. Most of the existing network pipes were in good shape and replacing them would have been expensive and wasteful. Instead, the team decided to re-engineer the existing network. This made it possible to lower the temperature yet maintain the temperature differential between the district network supply and return. This was achieved by altering some building connections to the district network. Rather than having each building receive its energy from the central plant (at a similar temperature), some buildings were connected in series, meaning that their heating supply would come from other buildings’ heating returns. Supplying buildings with the highest hot-water temperature requirements first, and then other buildings with lower temperature requirements, allows more heat to be extracted from the new district network, even though it now operates at a lower temperature. This cost-efficient, innovative design shortened the implementation timeline, reduced unnecessary waste, and minimized disruptive work for the campus regular activities.

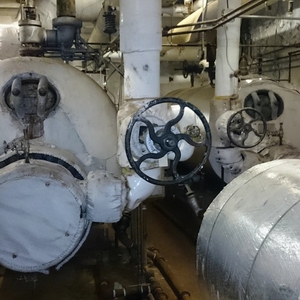

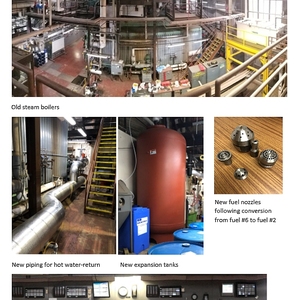

Stage 3: Improving the efficiency of energy-generating assets The lower-temperature network now made it possible to upgrade the central steam plant. Three 80 MMBtu/h steam boilers were converted from high-pressure steam to hot water, along with the installation of new valves, expansion tanks, and controls. This was deemed possible following an extensive analysis of the existing boilers, which were still in great shape. These changes included the removal of water treatment components like the deaerator and the pressure relief valve (PRV), which were no longer useful. This conversion also greatly reduced the water consumption of the central plant, since steam boilers periodically require their water to be flushed down and replaced, but hot water boilers do not.

Background

In 2008, the campus set an ambitious goal to reduce GHG emissions by 42% from 2007 levels by 2020. With this goal in mind, the Office of Sustainability established a program to fund the energy efficiency measures. Utility incentives received as rebates from National Grid are directed into the fund, enabling future initiatives. This supplemental source of funding for the university’s annual GHG reduction budget allows the Office of Sustainability to support facilities improvements to provide greater value, by combining asset renewal with additional energy efficiency. Thus far, the energy fund has paid for lighting retrofits, controls optimization and retro commissioning of HVAC systems across the campus, and fuel-switching from oil to natural gas at the campus heating plant.

By 2015, many of the “low-hanging-fruit” measures had already been implemented, and little more could be achieved on that front. The Office of Sustainability’s attention turned to the next phase in achieving the 2020 goal: the campus district heating system. The high-temperature and high-pressure district network was not compatible with any of the latest clean, high-efficiency technologies. But most of the buildings were relying on these operating conditions to fulfill their required space heating or process needs. It was clear that small, incremental steps would not have sufficient impact. A transformational project of the district heating system – potentially involving re-engineering and overhauling the central heating plant, distribution network and some building HVAC systems – was necessary. That plan, the Thermal Efficiency Project, was launched at the end of 2017. It involved converting Brown’s existing high-temperature hot water system – based on centrally produced high-pressure steam – to modern, highly efficient, lower-temperature hot water.

During the procurement process, rather than specifying the exact type of equipment and systems to be replaced Brown set the goals, the outcomes to be reached and the financial parameters. This gave the partnering firm the freedom, and responsibility, to design and implement the best solutions to meet Brown’s operational, financial, and environmental goals. Ecosystem committed to delivering the campus’s desired outcomes, developing the best solution and contractually guaranteeing the outcomes. This approach transferred a good portion of the technical and financial risks from the campus to the firm.

As required by Brown, the energy efficiency part of the investment will meet their internal rate of return (IRR) criteria of 8.5% with $1 million in annual utility savings. Ecosystem is contractually guaranteeing these savings. In case of any shortcoming, $500,000 worth of project improvement will have to be performed at Ecosystem’s expense.

Goals

The Thermal Efficiency Project’s main goal was to upgrade the district heating network in the most cost-effective way, creating a high-efficiency asset that the campus could build upon in the long term. The project reduced energy use and helps to achieve the ambitious GHG emissions reduction targets, but it also opens the door to future implementation of high-efficiency technologies and green energy sources. The project had two financial aspects: asset renewal, where most improvements would not generate any financial return; and energy efficiency, for the upgrades that would generate energy consumption and utility savings. For the energy efficiency aspect, the goal was to meet an IRR of 8.5%. The cost effectiveness criteria favored a lean approach, where existing infrastructure that was in good shape could be reused rather than replaced. This greatly reduced the costs of demolition and disposal of existing equipment and assets.

Implementation

The project’s main team members are:

- Dave Larson, Project Manager and Senior Energy Engineer, Brown University

- Jessica Berry, Director, Office of Sustainability, Brown University

- André-Benoît Allard, Senior Project Director, Ecosystem

- Frederick Marchand, Project Engineer, Ecosystem

- Jean-Philippe Rondeau, Senior Construction Manager, Ecosystem

For each building, collaboration between engineering, facilities, researchers, and faculty determined the acceptable level of impact to building operations. Any equipment delivery or shutdown involving heating, cooling, ventilation, or electricity required an intervention plan, outlining the steps and risk mitigation actions. In critical buildings, such those housing sensitive research, weekly coordination meetings were held to plan and communicate three-weeks’ work plans to stakeholders. For example, a timeframe for equipment shutdown during certain seasons was agreed on by all parties involved. An implementation schedule was then carefully reviewed to ensure that the design could be installed during these windows. Sometimes designs were altered to accommodate critical campus needs. In one instance, when heat recovery and preheating outside-air systems were to be installed – requiring two separate coils – a custom coil was developed instead that would need only one installation and shutdown.

Timeline

- 2008 - Brown sets ambitious goal to reduce GHG emissions by 42% in 2020, compared to 2008 levels.

- 2014-2016 - Detailed study of opportunities to increase efficiency at Brown’s central steam plant

- 2016-2017 - Project development and generation of solution; Conceptual design and engineering for the Thermal Efficiency Project

- Late 2017 - Design-build contract signed

- 2018-2020 - Detailed design and engineering phase by phase; Implementation

- End 2020 - Project optimization; Performance monitoring begins

Financing

- Total project investment: $24.8 M

- Asset renewal component: $16.3 M

- Energy efficiency improvement component: $8.5 M

- Financial incentives: $2 M

- Annual savings: $1 M

- Internal rate of return (IRR): 8.5%

The project successfully leveraged Brown's asset renewal budget which, in addition to financial incentives and utility savings, is funding this large scale project. Close collaboration between the finance and facilities departments early in the design stage was critical. This enabled to not only update the district network, but to deliver one that is more efficient, generates utility savings and is compatible with future high efficiency/green energy investments.

Results

The project has clearly supported Brown’s administration’s vision. The vintage district heating network was the elephant in the room: the biggest hurdle to achieve more ambitious energy consumption and GHG emissions reductions. Now that this milestone has been achieved, Brown can build from that to achieve more ambitious decarbonization goals.

This project also enhances Brown’s strong identity as a leading institution taking roots in the tradition, but at the cutting edge of fight against climate change.

Sustainability is a major focus of the University from student groups to the President. This transformative project embodied the idea of joining forces toward a common goal, with its multidisciplinary teams and many stakeholders.

Multiple outcomes with one project

- The project has already reduced heat losses from the district network. The supply temperature has dropped from 330F to 250F while still providing the same level of comfort and addressing all the process loads, greatly reducing fossil fuel consumption. Although the project itself reduces GHG emissions, it also establishes a high-efficiency infrastructure foundation on which Brown will build to reach its ambitious goals.

- The project enabled Brown to update their emissions goal in 2019, to reach net-zero emissions by 2040 with an interim goal of reducing emissions by 75% by 2025 from its 2018 baseline.

- The project is expected to reduce natural gas consumption by 91,000 MMBtu per year, which will reduce GHG emissions by 4,700 MTCDE per year.

- Water consumption has been reduced, thanks to the conversion of the central plant’s three steam boilers to hot water.

- With conservation a focus in material selection and waste reduction, the entire project was designed and implemented with a reuse and repurpose approach. As described in the section Project Overview – Stage 2, most of the existing piping was reused by keeping the same temperature differential in the loop, despite an overall lower temperature. Building on the Thermal Efficiency Project, the campus will be able to implement high-efficiency technologies and increase the electrification of their assets and purchase of clean energy.

- The project has received an honorable mention for the 2021 SCUP Awards - Excellence in planning - District or Campus Component

Lessons Learned

The key lessons from the development of the Thermal Efficiency Project, and recipes for success, were already starting to be evident toward the end of the design phase. They include the following:

- An effective decarbonization strategy starts with reducing the energy demand and energy consumption at the full campus level. This requires planning but, when well executed, can pay for itself with financial incentives, utility savings and asset renewal budgets. This is also a smart way to ensure that your energy network is compatible with future electrification of the heating loads.

- Long-term master planning and asset renewal plans can turn piecemeal or response-based projects into something more transformational that goes beyond the sum of the project’s parts. It delivers maximum energy efficiency and financial gains as well as optimized financial incentives.

- Empowering a sustainability department that is aligned closely with the facilities management of an institution allows institutional goals to be met.

- Involving all campus stakeholders in the design process ensures that the project can be developed with all needs in mind, prevent activity disruptions during construction. Not doing so could lead to some stakeholder reluctance over some aspects of the project and timeline delays.

- An outcome-based business model, where goals are specified rather than equipment specs, favored a collaborative approach with the partnering firm, which was accountable for meeting the desired outcomes. This approach translates particularly well to higher education institutions, since it provides custom solutions that address specific strategic goals. When the partnering firm can contractually guarantee the outcomes, a great part of the risk is transferred from the client to the firm.

- The integrated engineering and construction approach allowed agile project management that mitigates risks and impacts on daily activities during a large-scale project.